OEM/ODM Manufacturer melamine chip and dip plate for Namibia Factories

OEM/ODM Manufacturer melamine chip and dip plate for Namibia Factories Detail:

| Specification | |

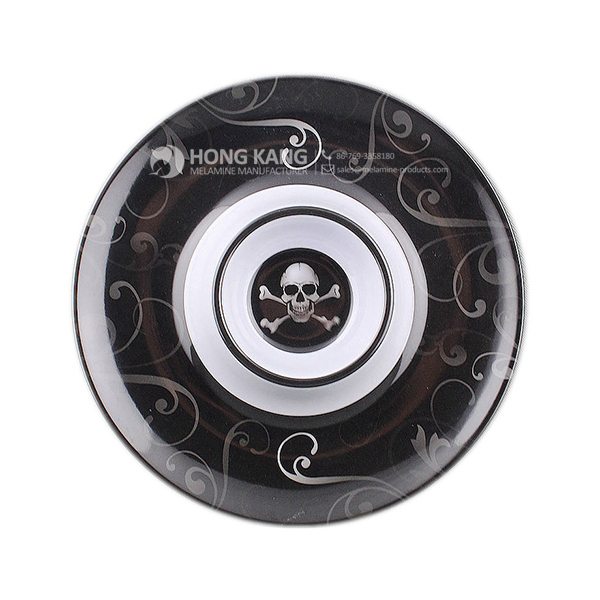

| Item Name | 13inch Round Melamine Chip and Dip Plate |

| Item No. | PT070 |

| Shape | Round |

| Body Color | White |

| Decal Color | 4 colors print |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 6pcs/box,24pcs/carton |

| Dimensions | |

| Length | 33 cm |

| Width | 33 cm |

| Height | 2.4 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 6.5 |

| Shipping Weight (kg) | 7.7 |

Product detail pictures:

Related Product Guide:

The Benefits Of Using Silicone Kitchen Utensils

Choosing The Best Dog Bowl and Feeder for Your Dog

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of OEM/ODM Manufacturer melamine chip and dip plate for Namibia Factories, The product will supply to all over the world, such as: Nigeria , United Kingdom , Malawi , Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

Reusable plastic corrugated box with Eva cushion packing to protect melamine bowl for catering ….recycle boxes for glass tray utensils and glass decoration lanterns by Aakar packart Vadodara Gujarat India 09376226980

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!