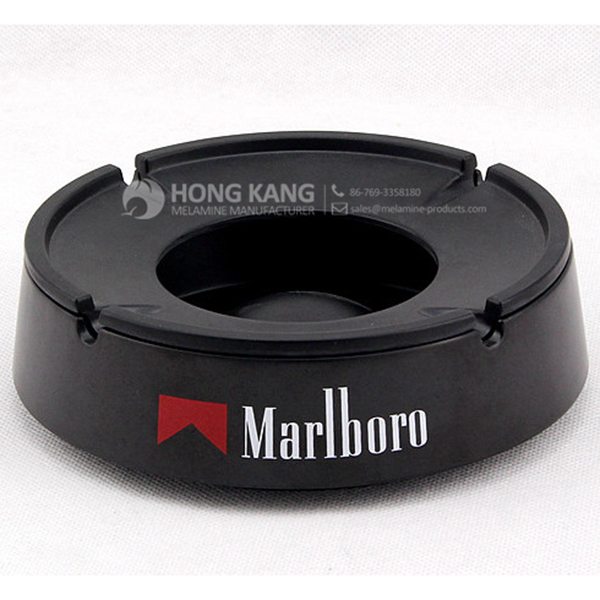

Factory provide nice price melamine windproof ashtray to Georgia Manufacturers

Factory provide nice price melamine windproof ashtray to Georgia Manufacturers Detail:

| Specification | |

| Item Name | 6inch Round Melamine Windproof Ashtray |

| Item No. | AT001 |

| Shape | Round |

| Body Color | Black |

| Decal Color | 4 colors print |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 20pcs/box,40pcs/carton |

| Dimensions | |

| Length | 14.5 cm |

| Width | 14.5 cm |

| Height | 4.5 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 8.8 |

| Shipping Weight (kg) | 10 |

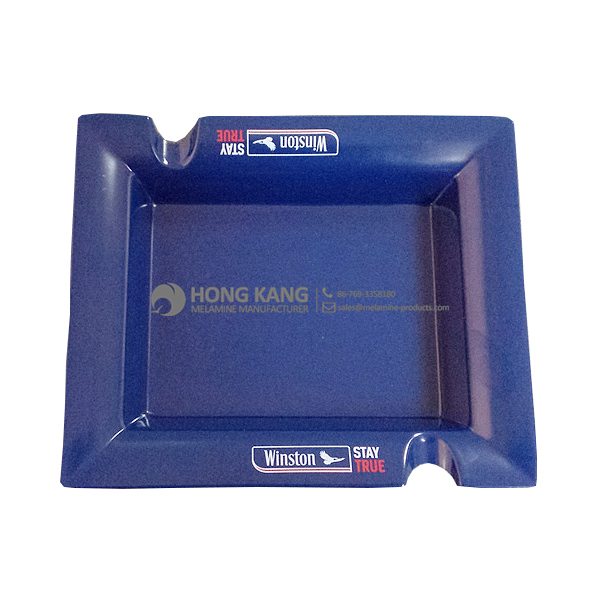

Product detail pictures:

Related Product Guide:

Choosing The Best Dog Bowl and Feeder for Your Dog

Benefits of Melamine Dinnerware

To be the stage of realizing dreams of our employees! To build a happier, far more united and far more specialist team! To reach a mutual profit of our customers, suppliers, the society and ourselves for Factory provide nice price melamine windproof ashtray to Georgia Manufacturers, The product will supply to all over the world, such as: Turkey , Netherlands , Czech republic , We pay high attention to customer service, and cherish every customer. We've maintained a strong reputation in the industry for many years. We are honest and work on building a long-term relationship with our customers.

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

Girnar Crafts Established 2000 at, Jaitpura, Jaipur, (Rajasthan, India). Girnar Crafts known as trusted name amongst the leading manufacturers, Suppliers and exporters of Sculptures, Statues and White marble Artefacts. In addition to this we manufacture and export classic decorative items, gift ware & utility products.

In this episode my wife coerces me into building some closet organizers for the kids’ closets by threatening to buy them from a manufacturer of mass produced furniture. The solution? Make them out of melamine particleboard. I take time out after a glue-up to explain what you need to know when working with melamine particleboard.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!