OEM/ODM Factory for melamine cutting board for United Arab Emirates Manufacturers

OEM/ODM Factory for melamine cutting board for United Arab Emirates Manufacturers Detail:

| Specification | |

| Item Name | 9.25inch Melamine Cutting Board |

| Item No. | PT133 |

| Shape | Rectangle |

| Body Color | White |

| Decal Color | 4 colors print |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 12pcs/box,48pcs/carton |

| Dimensions | |

| Length | 23.3 cm |

| Width | 14.3 cm |

| Height | 0.3 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 7.2 |

| Shipping Weight (kg) | 8.5 |

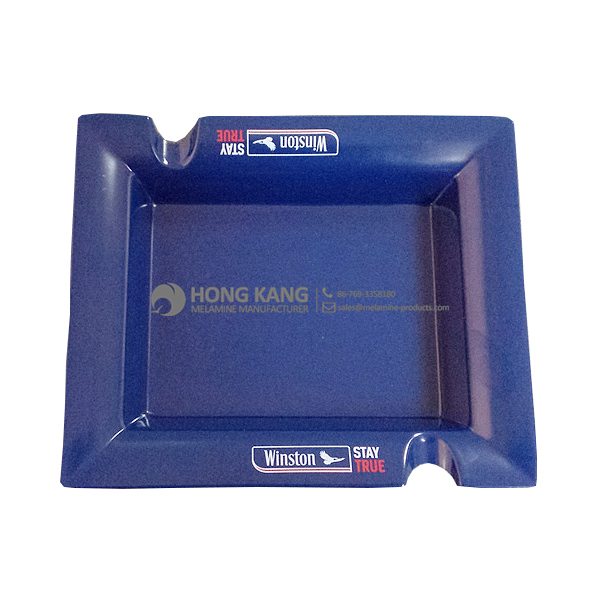

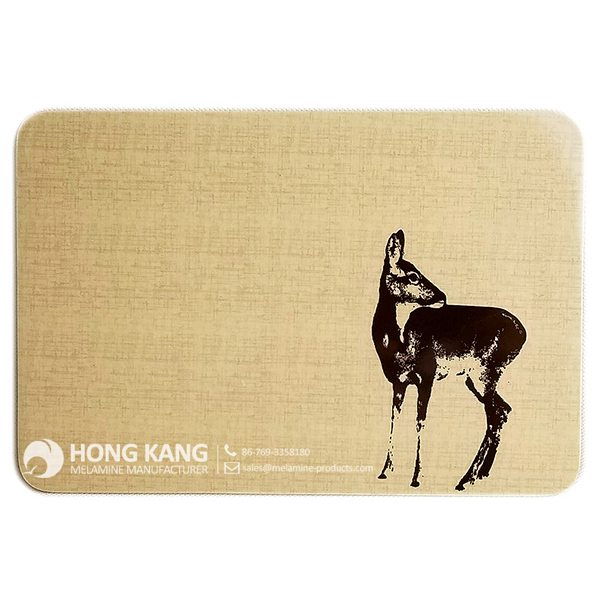

Product detail pictures:

Related Product Guide:

Benefits of Melamine Dinnerware

Affordable Types of Dinnerware Sets

Bear "Customer 1st, Good quality first" in mind, we work closely with our prospects and supply them with efficient and professional services for OEM/ODM Factory for melamine cutting board for United Arab Emirates Manufacturers, The product will supply to all over the world, such as: Milan , Wellington , Zimbabwe , Our products are very popular in the word, like South American, Africa, Asia and so on. Companies to "create first-class products" as the goal, and strive to deliver customers with high quality solutions, present high-quality after-sales service and technical support, and customer mutual benefit, create a better career and future!

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

Just a review video covering some of the molds I used for making my resin pieces, plus show-offs of some finished pieces from the molds. Look below for links to where I bought them.

Batman: http://www.amazon.com/gp/product/B00JPIQSEU?psc=1&redirect=true&ref_=oh_aui_detailpage_o03_s00

Serenity: http://www.thinkgeek.com/product/1867/?srp=5

Skull and Crossbones: http://www.amazon.com/gp/product/B0014A6BY4?psc=1&redirect=true&ref_=oh_aui_detailpage_o03_s00

Gummy Bear: http://www.thinkgeek.com/product/ee56/?srp=2

Tetris: http://www.amazon.com/gp/product/B008NZHFPM?psc=1&redirect=true&ref_=oh_aui_detailpage_o03_s00

Loot Crate Marvel: http://www.amazon.com/Marvel-Avengers-Cube-Tray-Crate/dp/B015T7YDUG

Dr. Who: http://www.thinkgeek.com/product/f247/?srp=1

Star Trek: http://www.amazon.com/gp/product/B00KWBHH2Q/ref=pd_lpo_sbs_dp_ss_1?pf_rd_p=1944687582&pf_rd_s=lpo-top-stripe-1&pf_rd_t=201&pf_rd_i=B00FS1S3CS&pf_rd_m=ATVPDKIKX0DER&pf_rd_r=1QDNJ581CCA1VGXDTY0F

Places to find me:

+Website: www.foxbones.com

+Etsy: https://www.etsy.com/shop/FoxBonesStudio

+Facebook: https://www.facebook.com/safetypinner/

+Instagram: @SafetyPinner

+Snapchat: fallingaction

+Periscope: @SafetyPinner

+Crafty Amino: @SafetyPinner

Music: “Der Kleber Sting” by Kevin MacLeod, www.incompetech.com

Crowdz is a global commerce platform with a local perspective. We believe in supporting the growth of local communities through commerce.

Our purpose is to create a community around commerce by building relationships not only between mobile buyers and local businesses but also from peer-to-peer.

Through Crowdz’s mobile commerce application, we are able to provide the best value on local products and services by leveraging the power of crowd buying.

The platform works by pooling together the community and developing micro economies of scale. [The more people purchase the same products as you, the more money is credited back to you. It’s that simple.]

Crowdz is the only mobile commerce platform that empowers both local residents and local businesses.

We do this through:

- Local Leaderz: A program that empowers local residents by giving them a percentage of sales from every small-medium local business that they bring to the Crowdz Marketplace.

- Crowd Buying: Opertates on the concept of economies of scale. The more people purchase a given product or service the more money you get back in your pocket.

- Rewardz: The money you get back from the power of crowd buying can be used either to donate to local charities of your choice or into future purchases – just like credit credit reward points

Some testimonies from users:

“New application that allows individuals to buy through other individuals to benefit and get a better deal”

“It is a win-win situation, we increase revenue to sellers and decrease cost of sales to buyers”

The real benefits, however, are the intangible ones we all love, like a truly personal shopping experience and the satisfaction of giving back to your community. Now imagine, all of this goodness right in the palm of your hand…that’s where Crowdz comes in.

Crowdz is a mobile commerce app that allows you to shop from local sellers in communities around the world, all from the convenience of your mobile phone.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!