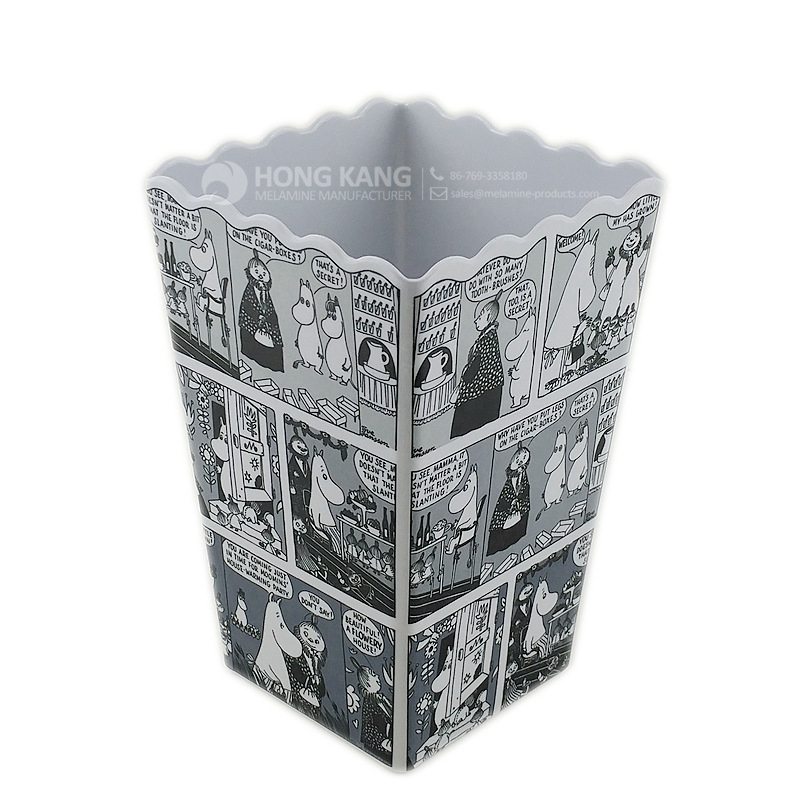

Factory Supplier for melamine popcorn bucket for Botswana Manufacturer

Factory Supplier for melamine popcorn bucket for Botswana Manufacturer Detail:

| Specification | |

| Item Name | 4inch Square Melamine Popcorn Bucket |

| Item No. | BW269 |

| Shape | Square |

| Body Color | White |

| Decal Color | 4 colors print (if need) |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 6pcs/box,24set/carton |

| Dimensions | |

| Length | 10 cm |

| Width | 10 cm |

| Height | 15.6 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 4.5 |

| Shipping Weight (kg) | 5.6 |

Product detail pictures:

Related Product Guide:

Choosing The Best Dog Bowl and Feeder for Your Dog

Benefits of Melamine Dinnerware

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" as well as the theory of "quality the basic, have confidence in the very first and management the advanced" for Factory Supplier for melamine popcorn bucket for Botswana Manufacturer, The product will supply to all over the world, such as: Brasilia , Marseille , India , The credibility is the priority, and the service is the vitality. We promise we have the ability to provide excellent quality and reasonable price products for customers. With us, your safety is guaranteed.

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

Subscribe to Happy Funny Kids Toys Pretend Play: https://www.youtube.com/channel/UCquMFVZvpf8eczgNSnCgYlw?sub_confirmation=1

Foam Ice Cream Cup Surprise Toys Mickey Mouse Peppa Pig Finding Nemo Kinder Eggs Fun for Kids https://youtu.be/pyTDrsQt9F8

More videos from Happy Funny Kids Toys Pretend Play:

Learn Colors Play Foam Ice Cream Cups Kinder Joy Kinder Egg Surprise Toys Barbie TMNT Fun for Kids HD

https://www.youtube.com/edit?o=U&video_id=tO7ipRSMaB4

Play Doh Balls Ice Cream Set Toys Learn Colors & Shapes Kinetic Sand Fun & Creative for Kids HD

https://www.youtube.com/edit?o=U&video_id=jUg0oIgY8T0

Learn Colors Play Doh Doraemon Fun & Creative for Kids Blind Bags Kinder Eggs Surprise Toys HD

https://www.youtube.com/edit?o=U&video_id=lcEqkX-115c

Learn Colors Play Foam Smiley Face Surprise Eggs Play Doh Balls Ice Cream Fun & Creative for Kids HD

https://www.youtube.com/edit?o=U&video_id=LTIYNISnNH8

Learn Colors & Shapes Play Doh Ice Cream Cups Surprise Eggs Disney Pixar Cars Toys Fun for kids HD

https://www.youtube.com/edit?o=U&video_id=6LZHFyNVm98

Chocolate Football Egg Bashing Surprise Toys Fun for Kids HD

https://www.youtube.com/edit?o=U&video_id=2qf5bELlk-c

Learn Colors Play Doh Balls Ice Cream Peppa Pig Elephant Molds Fun & Creative for Kids Kinder Eggs HD

https://www.youtube.com/edit?o=U&video_id=PmpjJPBOVFM

Chocolate Football Egg Surprise Toys Disney Princess Fashems Ariel Cinderella Shopkins Barbie

Learn Colors and Shapes with Play Doh Moldelling Clay Baby Shape Sorting Fun & Creative for Kids

Learn Colors with Play Foam Happy Sad Smiley Face Surprise Eggs Disney Princess Thomas & Friends Fun

Music from YouTube audio library https://www.youtube.com/audiolibrary/music

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!