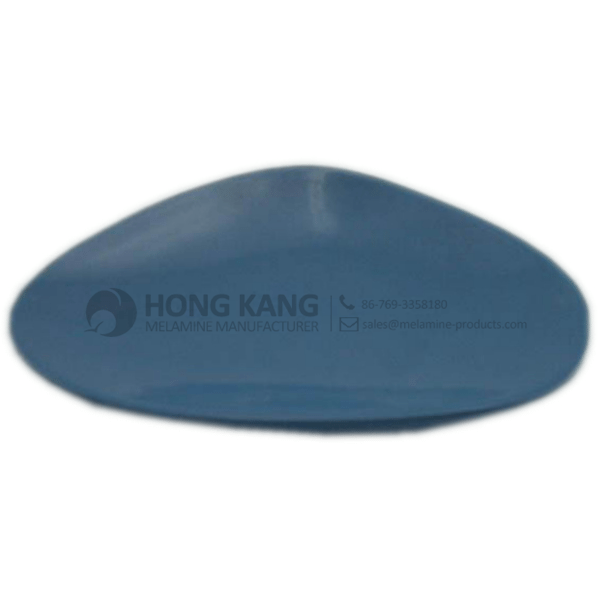

factory customized melamine soap dish to Jakarta Manufacturer

factory customized melamine soap dish to Jakarta Manufacturer Detail:

| Specification | |

| Item Name | 5.5inch Triangle Melamine soap dish |

| Item No. | PT223 |

| Shape | Triangle |

| Body Color | Blue |

| Decal Color | 4 colors print (if need) |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 12pcs/box,72pcs/carton |

| Dimensions | |

| Length | 14 cm |

| Width | 10 cm |

| Height | 1.5 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 6.4 |

| Shipping Weight (kg) | 7.5 |

Product detail pictures:

Related Product Guide:

Benefits of Melamine Dinnerware

Top Ten Power Toothbrushes

"Control the quality by the details, show the strength by quality". Our company has strived to establish a highly efficient and stable staff team and explored an effective quality control process for factory customized melamine soap dish to Jakarta Manufacturer, The product will supply to all over the world, such as: Swiss , Estonia , Cairo , The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

Three hopeful inventors make their pitches to our judges as they compete to become TODAY’s Next Big Thing and sell their products on QVC this weekend: John Esquivel with his Perfect Taco Shaper; Yair Reiner with the Frywall splatter guard, and Laura Ivy, who’s pitching the Skrub Knife Cleaner. Vote for your favorite on TODAY.com.

» Subscribe to TODAY: http://on.today.com/SubscribeToTODAY

» Watch the latest from TODAY: http://bit.ly/LatestTODAY

About: TODAY brings you the latest headlines and expert tips on money, health and parenting. We wake up every morning to give you and your family all you need to start your day. If it matters to you, it matters to us. We are in the people business. Subscribe to our channel for exclusive TODAY archival footage & our original web series.

Connect with TODAY Online!

Visit TODAY’s Website: http://on.today.com/ReadTODAY

Find TODAY on Facebook: http://on.today.com/LikeTODAY

Follow TODAY on Twitter: http://on.today.com/FollowTODAY

Follow TODAY on Google+: http://on.today.com/PlusTODAY

Follow TODAY on Instagram: http://on.today.com/InstaTODAY

Follow TODAY on Pinterest: http://on.today.com/PinTODAY

Three Inventors Compete To Be TODAY’s Next Big Thing On QVC | TODAY

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.