Customized Supplier for melamine chip and dip plate to New Delhi Factories

Customized Supplier for melamine chip and dip plate to New Delhi Factories Detail:

| Specification | |

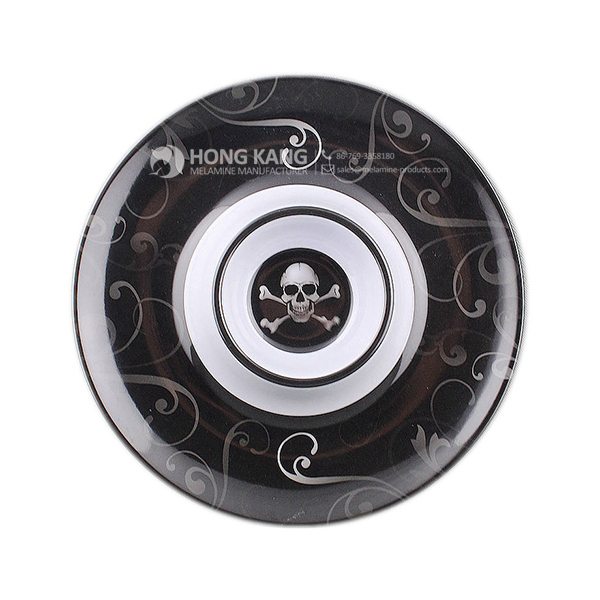

| Item Name | 13inch Round Melamine Chip and Dip Plate |

| Item No. | PT070 |

| Shape | Round |

| Body Color | White |

| Decal Color | 4 colors print |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 6pcs/box,24pcs/carton |

| Dimensions | |

| Length | 33 cm |

| Width | 33 cm |

| Height | 2.4 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 6.5 |

| Shipping Weight (kg) | 7.7 |

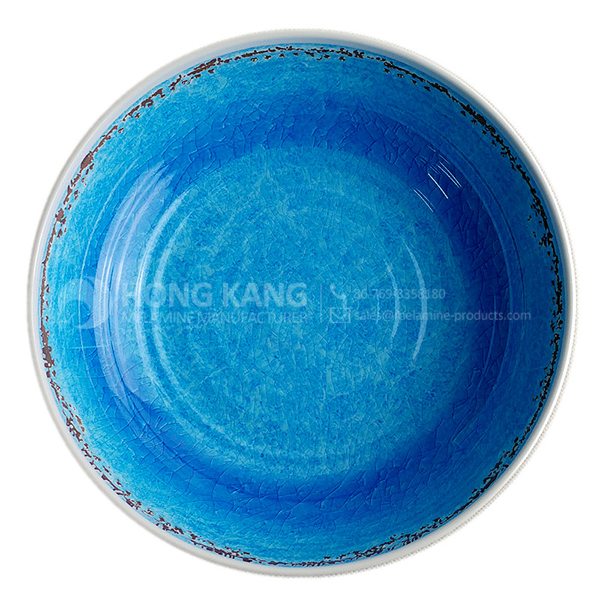

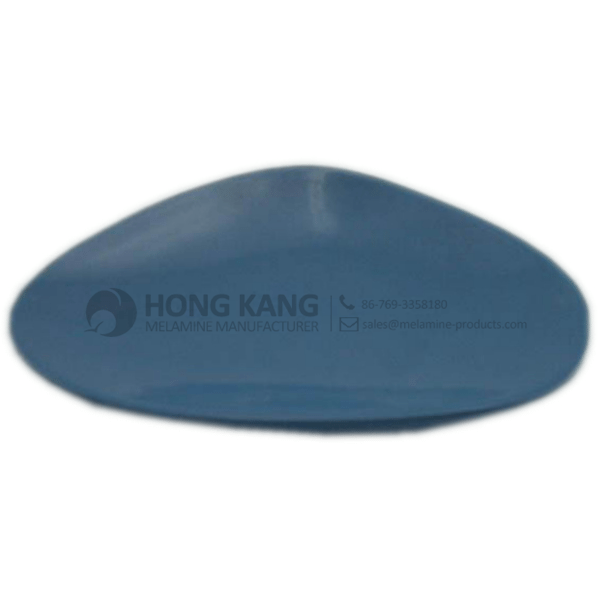

Product detail pictures:

Related Product Guide:

Benefits of Melamine Dinnerware

Top Ten Power Toothbrushes

We insist over the principle of development of 'High top quality, Performance, Sincerity and Down-to-earth working approach' to supply you with exceptional services of processing for Customized Supplier for melamine chip and dip plate to New Delhi Factories, The product will supply to all over the world, such as: Auckland , Cyprus , Belgium , Our solutions have national accreditation standards for experienced, premium quality items, affordable value, was welcomed by people around the globe. Our goods will continue to increase in the order and look forward to cooperation with you, Really should any of those products be of interest to you, please letus know. We are going to be pleased to give you a quotation up on receipt of one's detailed specifications.

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!