15 Years Manufacturer melamine cutting board to Zimbabwe Manufacturer

15 Years Manufacturer melamine cutting board to Zimbabwe Manufacturer Detail:

| Specification | |

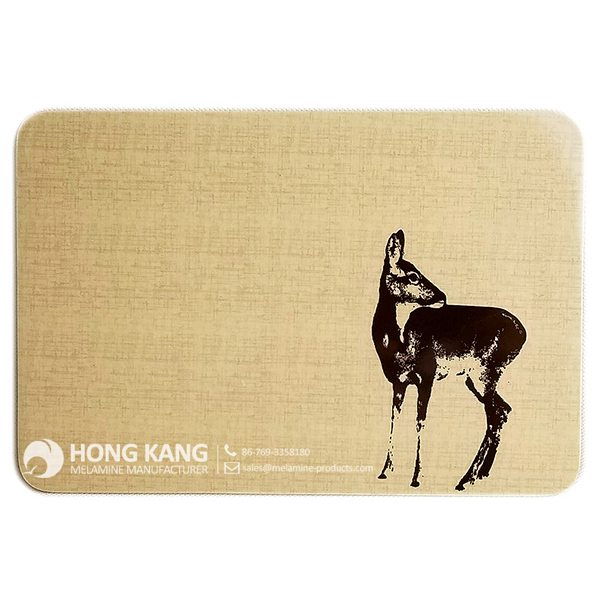

| Item Name | 9.25inch Melamine Cutting Board |

| Item No. | PT133 |

| Shape | Rectangle |

| Body Color | White |

| Decal Color | 4 colors print |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 12pcs/box,48pcs/carton |

| Dimensions | |

| Length | 23.3 cm |

| Width | 14.3 cm |

| Height | 0.3 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 7.2 |

| Shipping Weight (kg) | 8.5 |

Product detail pictures:

Related Product Guide:

The Benefits Of Using Silicone Kitchen Utensils

Affordable Types of Dinnerware Sets

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for 15 Years Manufacturer melamine cutting board to Zimbabwe Manufacturer, The product will supply to all over the world, such as: Buenos Aires , Bandung , St. Petersburg , Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.