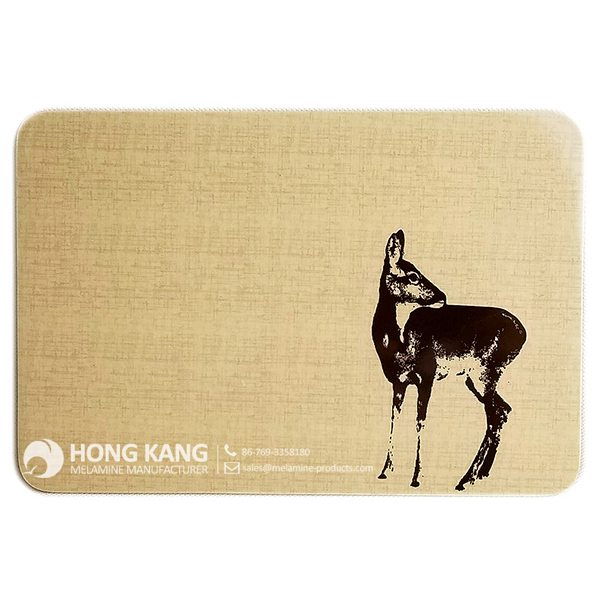

11 Years Factory wholesale melamine cutting board for London Manufacturer

11 Years Factory wholesale melamine cutting board for London Manufacturer Detail:

| Specification | |

| Item Name | 9.25inch Melamine Cutting Board |

| Item No. | PT133 |

| Shape | Rectangle |

| Body Color | White |

| Decal Color | 4 colors print |

| Finish | Glossy |

| Style | Fashion |

| Motif Design | Customized |

| Shape Design | OEM/ODM |

| Test Standard | FDA,PROP 65,EN71,LFGB etc. by SGS or ITS |

| Packaging | 12pcs/box,48pcs/carton |

| Dimensions | |

| Length | 23.3 cm |

| Width | 14.3 cm |

| Height | 0.3 cm |

| Capacity | N/A |

| Material | |

| Body Material | 100%melamine |

| Decal Material (if need) | 4 colors print (CMYK), or spot color printing, RoHS certificate |

| Imprint (if need) | Seiko ink type 1000 or other type, RoHS certificate |

| Accessories Information | |

| Lid included | No |

| Other | No |

| Weights | |

| Net Weight (kg) | 7.2 |

| Shipping Weight (kg) | 8.5 |

Product detail pictures:

Related Product Guide:

Top Ten Power Toothbrushes

Benefits of Melamine Dinnerware

"Based on domestic market and expand abroad business" is our enhancement strategy for 11 Years Factory wholesale melamine cutting board for London Manufacturer, The product will supply to all over the world, such as: Lesotho , Mauritania , Rome , Over the years, with high-quality products, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

FAQ: 1.Q: Where is your factory located? How can I visit there? A: Our factory is located in Guangdong province, China. Warmly welcome to visit us! 2.Q: What is the material of your products? A: The material is melamine. 3.Q: How can I get some samples? A: We can send the samples by Express/DHL/FedEx/UPS etc. 4.Q: How does your company do regarding quality control? A: We have a very strict QC system. Our inspectors have been closely monitoring the production process from the selection of raw materials to the final step of the finished products. 5.Q: Can you print our logo on the product & packing? A: Yes, We can print your logo on our products.

| * Do Not Touch On Fire Directly | |

|---|---|

| * Do Not Washing By Steelwire Ball | |

| * Non-Microwave Ovens | |

| * Dishwasher Safe |

Automated 5 bowl hardware counting packaging machine with bucket chain conveyor operator stations

Hardware counting packing machine with 5 bowls

Application:

It is applicable to industry product’s counting and packing automatically. Such as screws, bolts, nuts, fasteners, small hardware or plastic, wooden products.

Technical Parameters:

Model YX-SPM005

Capacity 20-50bags/min

Counting range customize according to requirements

Bag size Width: 30-130mm,Length: 30-145mm or customize

Sealing type back side sealing

Voltage 220V/50-60HZ or customize

Power 3KW

Packing material opp/pe, opp/cpp, al/pe or other plastic film

Machine dimension (L)2800*(W)1600*(H)1450mm

Features:

1.The vibration bowl, linear vibration unit and precise counting control unit are customize according to the products.Ensure precision counting quantity of each bag.

2.Misubishi PLC control, and there is Chinese and English human-machine operation interface,it is easy to operate. High degree of automation.

Hardware counting packing machine with 5 bowls

Our Factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.

For more information about penglai packaging, please visit our website at http://penglaipacking.com

SHENZHEN PENGLAI INDUSTRIAL CORPORATION LIMITED

Contact:Michael Peng Skype: penglaichina Email: penglaipacking@gmail.com whatsapp:+86-15012795261

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.